Ceiling ventilation systems matter more than most people realise. Especially in busy commercial kitchens, where heat, smoke and steam can build up fast. One option more kitchens are turning to is a plenum ceiling ventilation system.

We’ll explain what a plenum ceiling system is, how it works, and why it might be the right choice for your kitchen.

What Is a Plenum Ceiling Ventilation System?

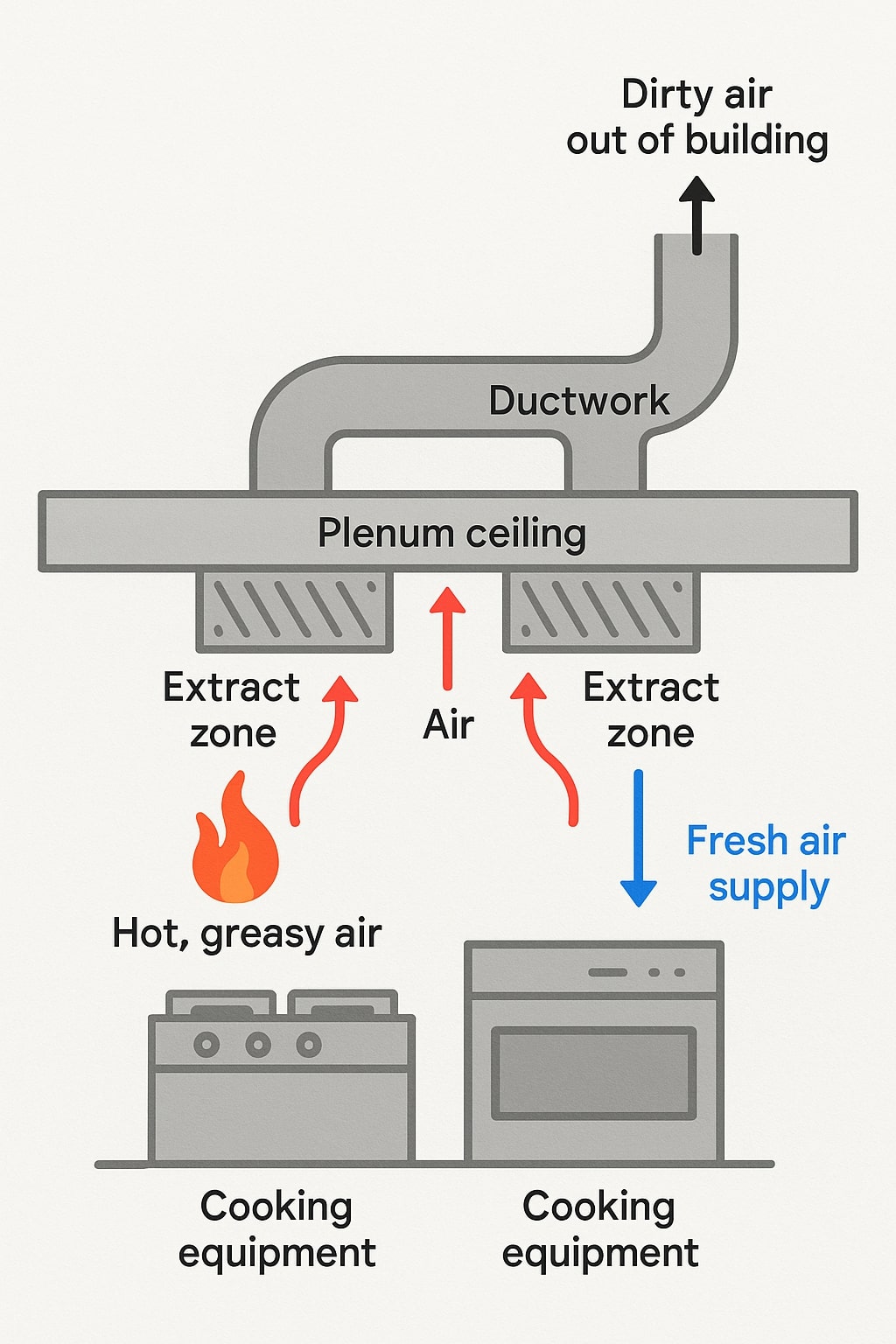

A plenum ceiling ventilation system is a special type of kitchen extraction and air supply setup. Instead of using traditional canopy hoods over each appliance, the whole ceiling becomes the extraction zone. Air is drawn up through grills across the ceiling and sent through ductwork above.

Clean air can also be supplied through the same ventilated ceiling system, keeping temperatures comfortable and airflow balanced.

Why Use a Plenum Ceiling in a Commercial Kitchen?

Plenum ceilings can help make kitchens more open, clean and efficient. They’re often used in modern cooking spaces, especially where the kitchen is visible to guests, such as open plan restaurants.

How Does it Work?

A plenum ceiling ventilation system in a commercial kitchen works like this:

- Hot, greasy air rises from cooking equipment.

- The plenum ceiling acts like a big hidden hood, covering the whole cooking area.

- Air is pulled through filters in the ceiling, which trap grease and smoke.

- The dirty air is extracted out of the building.

- Fresh air is supplied back into the kitchen through the same system.

It’s cleaner looking, quieter, and can cover large kitchen setups without bulky overhead hoods.

What Equipment Works with a Plenum Ceiling System?

Plenum ceiling systems are designed to work with standard catering appliances, from fryers to ovens and grills. However, there are some points to consider:

Heat levels: If your appliances give off a lot of heat (such as solid fuel grills or wok ranges), the ceiling must be designed to deal with it. This may mean more extraction points or stronger fans.

Grease production: Kitchens which deal with a lot of greasy cooking may need advanced grease filtration systems, such as UV filters to catch airborne grease before it hits the ducts.

Key Benefits of Plenum Ceiling Systems

Better Hygiene

Plenum ceilings create fewer gaps and corners where grease and dirt can build up. The ceiling panels are easy to wipe clean and primarily made from stainless steel.

Comfort and Airflow

Plenum ceilings create fewer gaps and corners where grease and dirt can build up. The ceiling panels are easy to wipe clean and primarily made from stainless steel.

Flexible Layout

Because there are no large hoods hanging down, the space above cooking areas stays clear. This gives designers and operators more freedom with how they arrange equipment and workstations.

Quiet Operation

These systems are often quieter than traditional extraction systems. The large ceiling surface allows air to move more slowly, which cuts down on noise.

How Can Corsair Help?

Plenum ceiling ventilation systems offer a cleaner, smarter way to manage air in your commercial kitchen.

If you’re considering a plenum ceiling system, or want to learn more about your options, get in touch with us today on 01295 267021 or email us – sales@corsairengineering.co.uk We’ll walk you through the benefits, answer your questions, and help you find the right setup for your space.

Let’s build a kitchen that works better – from the ceiling down.